3D Printing Systems for a new Paradigma in Jewellery

3D printing is changing the way to produce, becoming a process which enables companies to transform and tweak product models much more easily and cost-effectively than by using traditional manufacturing methods.

DWS develops and produces the technology, materials and software giving a new experience to professionals during the production of jewellery models. DWS aims to reduce development times of the production ensuring the best quality in terms of precision and resolution.

Due to their reduced moving parts and unique user-friendliness, DWS’ 3D printers are characterised by high reliability and extra-low maintenance.

A great flexibility is made possible by the quick material change, the absence of pre-heating and calibration. The machines are controlled by dedicated software that is perfectly compatible with most 3D CAD systems used in the jewelry applications.

BluEdge® is a Class 3B laser source created by DWS Research & Development that emits ultraviolet rays which solidify layer upon layer the photosensitive resin.

Professional Materials for Jewellery and Fashion Accessories

The materials are designed, developed, and produced in-house by DWS, to guarantee the quality of the finished product and an easy direct casting.

They are specifically developed for obtaining the highest resolution in the production of filigrees, thin details, complex patterns and solid design.

Discover all DWS materials through the Material Finder and find out the best solutions for your profession.

3D PRINTERS FOR JEWELLERY

AND FASHION ACCESSORIES

029XC

029XC is a solution for rapid manufacturing designed for medium-high production volumes.

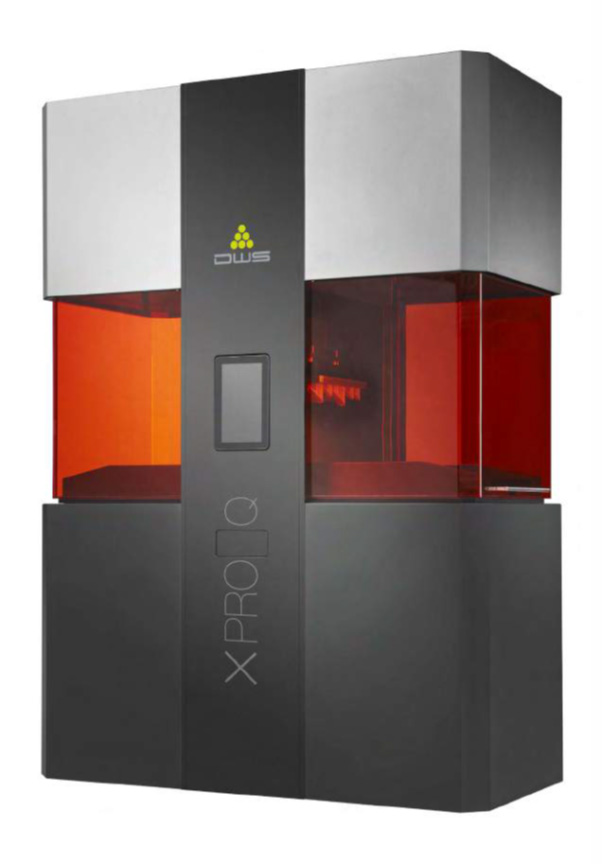

XPRO Q

XPRO Q is a stereolithographic 3D printer capable of the highest levels of productivity and quality in the jewellery sector.