London’s 3Dprintshow just opened and Sharebot put all its cards on the table.

Togheter with Sharebot Q (an A3 format 3D printer with a fully automated calibration system), Sharebot SnowWhite (a sintering laser 3D printer with polymeric powders) and Sharebot XXL (a large build FFF 3D printer), it was presented the fourth product badged Sharebot R&D: Sharebot Voyager.

Sharebot Voyager is a 3D printer based on the DLP (Digital Light Processing).

This technology consists in the realization of high precision objects through the using of special liquid resins which are subjected to a process of hardening caused by the light released from a projector.

Resins are placed in special easily interchangeable trays and all of them are internally developed by Sharebot R&D: our researchers are testing a lot of different resins to understand the compatibility that they can have with the printer. The goal is being able to deliver a range of products in many colors and 100% castables.

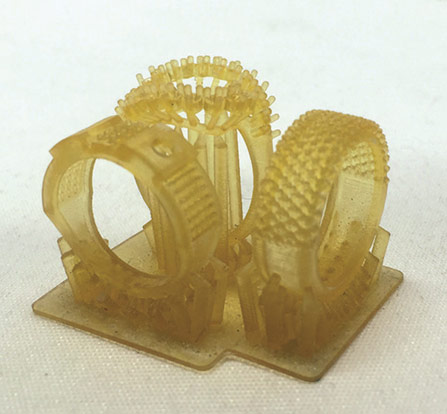

Voyger printing area is 100x50x100mm. It also has an XY definition of 50 microns and a layer high of 25 to 100 microns. All these charecteristics allow you to realize small object with a very high definition and great precision: because of that, Sharebot Voyager could be used a lot of professional fields like the goldsmith’s art and the odontology where the need for the the feature is crucial.

The projector that allows the resin solidification has a resolution of 1920 x 1080 pixels and a power of 3000 ANSI lumens. You can create an object at a print speed approximately of 170 cm cube per hour (this figure is likely to change for technical reasons).

The printer is equipped with a software fully realized by our R&D Department allowing you to print wireless from any computer as Voyager is 100% compatible with any computer with an internet connection.

Sharebot Voyager certifies the commitment with which our company research new solutions for 3D printing even in little-known and still largely unexplored fields

Sharebot Voyager-2

Sharebot Voyager-2 is the professional 3D printer that uses DLP technology to create objects with high precision, ideal for prototypes and models that need great definition even in the smallest details.

The integrated professional FULL HD projector hardens the printing material, the resin, with a UV ray that impresses the image on the material which, once lit, solidifies. Thanks to the vertical movement of the Z axis of the printer, the process is repeated layer by layer until the object is generated. This process allows to have perfectly smooth surfaces in a short time: thanks to the rapid solidification of the resin the production times undergo a drastic decrease, making Sharebot Voyager-2 the ideal working tool for dental technicians, modelers and all those sectors where the precision of the smaller details makes the difference.

The printer management and control software are integrated: you can create and generate supports for your object on the PC and send them via the network to the printer, then checking the entire printing process remotely.