DWS, Digital Wax Systems

TechnoVision has been marketing the most advanced technology in Additive Manufacturing, the DigitalWax machines which are manufactured by DWS s.r.l. of Italy.

Hi-tech solutions for prototyping and high-speed production applied to reduce development times for new industrial products (time to market), systems that have become a strategic resource and must-have elements for corporate competitiveness.

Features of DigitalWax Machine

- High surface quality

- High Productivity

- Available resins for rubber moulds

- Lowest running cost in the market

- Ideal resin for direct casting

- 1 Year warranty

- Excellent Casting performance

- 7 Models to suit your requirement

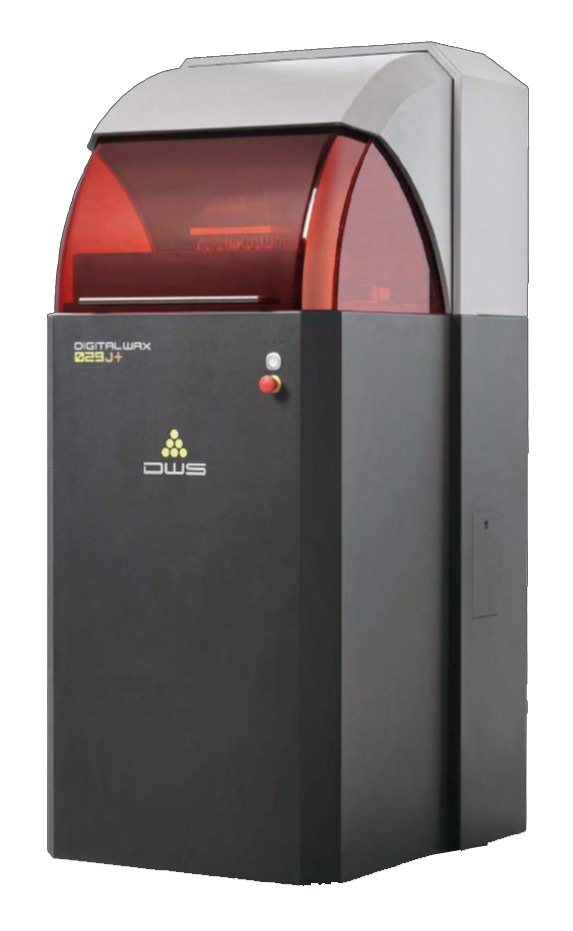

029J Series

029J is a high-speed, high-precision SLA 3D printer for rapid manufacturing in the jewellery industry. Specifically developed for medium and large-sized jewellery workshops, it is ideal for big-name brands demanding a top reliable printer with a large printing area that can produce pieces of the highest quality, precision and resolution, in big quantities.

029J family can produce up to 270 pieces per day (depending on the complexity) to an extremely high level of detail, including smooth surfaces, undercuts, cavities, and filigrees, ensuring the greatest freedom when designing.

With extremely low running and maintenance costs, the printer has been designed to operate continuously, always ensuring the maximum reliability and consistency. Together with the integrated Nauta Plus software that automatically generates the support structures, the system is compatible with the entire range of materials developed by DWS for jewellery applications.

029XC

029XC is a solution for rapid manufacturing designed for medium-high production volumes. It grants high speed, precision and an increased working area to maximize the productivity.

029XC runs both the proprietary Nauta Plus software (that allows the automatic generation of supports) and its special (optional) module XCluster*, dedicated to the easy building of trees for lost wax casting productions. Thanks to the combination among materials, its precision and the specifically designed software,

the workflow becomes totally digital and automated. This increases productivity, reduces time-to-market, production times and consequently costs in the different application fields. With extremely low running and maintenance costs, the printer has been designed o operate continuously, always ensuring the maximum reliability and consistency.

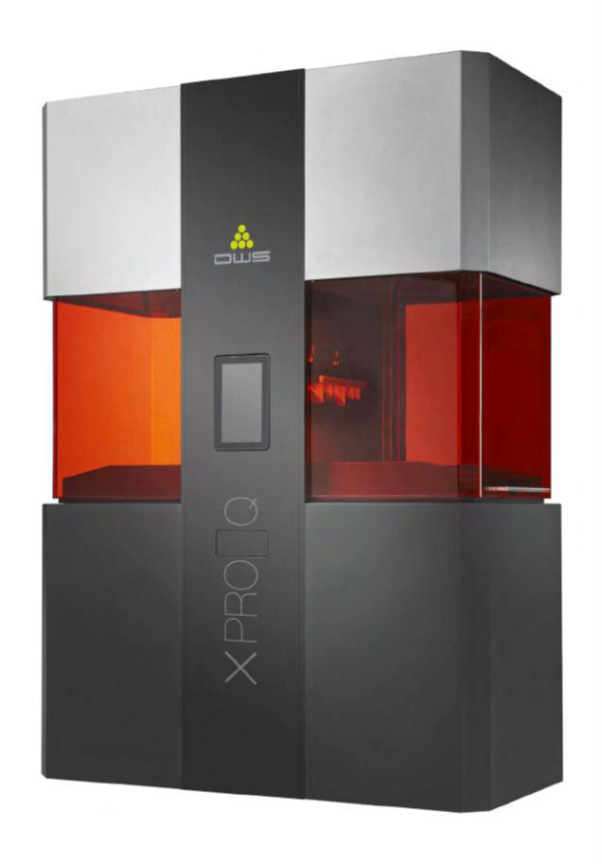

XPRO Q

XPRO Q is a stereolithographic 3D printer capable of the highest levels of productivity and quality in the jewellery sector. This reliable 3D printer boasts a large printing area and can produce models of the highest quality, precision and resolution. It is designed for large businesses, third-party manufacturers, and big-name brands in the jewellery industry and can produce up to 3,200 models per day (depending on complexity) to an extremely high level of detail, including smooth surfaces, undercuts, cavities and filigrees while offering the greatest freedom for the designer. XPRO Q runs both the proprietary Nauta Plus software (that allows the automatic generation of supports) and its special (optional) module XCluster*, dedicated to the easy building of trees for lost wax casting productions. XPRO Q is the perfect 3D printing system for the production of large quantities of models for direct casting and rubber moulding within a short time. With low running costs and zero planned maintenance costs, XPRO Q has been designed to operate continuously, always ensuring the maximum reliability and consistency. The system uses SLA technology to obtain the extremely high resolution and precision that the industry demands and it is compatible with the entire range of materials DWS has developed for jewellery applications. The system includes an integrated touch screen computer, making it easy to launch print jobs, and four Solid State BluEdge laser sources working simultaneously to ensure the fastest production times.